The future of metal packaging

Author/ He Xiaogang, Zhang Zhengchang, Liao Shilong Shenzhen Daman Packaging Co., Ltd.

Metal packaging plays an extremely important role in the four major packaging materials, and plays an increasingly important role in social life. Metal packaging has an important and irreplaceable role in the food and beverage industry by virtue of its exquisite printing, durability, easy opening, and better sealing performance than paper packaging and plastic packaging.

According to the World Packaging Industry Association statistics, in China, Japan and Europe, the amount of metal packaging used in the total amount of packaging materials is third, behind paper packaging and plastic packaging. In the United States, the amount of metal packaging occupies second of the replacement of plastic packaging, while paper packaging still sits in the head of the packaging industry.

Two factors make the amount of metal packaging increase substantially

Plastic waste is prohibited from exporting to China, so that the application of plastic packaging is inhibited. As most plastics are not degradable, in order to further standardize the management of solid waste import and prevent environmental pollution, according to the law on the prevention and control of environmental pollution of solid waste in People's Republic of China, the measures for the administration of solid waste import and the relevant laws and regulations, the Ministry of ecological environment, the Ministry of Commerce, the development and Reform Commission and the General Administration of customs are in force. The catalogue of solid wastes which can be used as raw materials for imported materials and the catalogue of prohibition of import solid waste have been adjusted, and the specific content of foreign waste is further clarified, in which the plastic waste is the first prohibited material to be imported.

According to official statistics from the United States, 1 million 400 thousand tons of plastic waste and 13 million 200 thousand tons of paper waste were exported to China in 2016. As China says no to "Foreign Garbage", the long-term export of waste to China by European and American countries will be controlled, which will force the countries to be more cautious about the use of plastic packaging.

Picture 1 The solid waste exported to China by the US in 2016

Excessive use of paper packaging will damage natural resources.The metal packaging is not only rich in resources, but also can be recycled for unlimited use. Because paper packaging materials are mainly derived from forest. Overuse it will cause great damage to natural resources. The metal material is not only rich in resources, but also can be used indefinitely. This shows that metal packaging will be promising in the future, and the volume of usage is expected to increase steadily.

According to the statistics and forecast of the international canning industry association, the global annual demand for metal cans is 364 billion 400 million in 2014, with a transaction amount of $44 billion 860 million. It is expected to reach 430 billion in 2020, with a transaction amount of $52 billion 830 million and a growth rate of 2.9%.

According to the relevant statistics, in the 10 years of 2006~2015, the use of metal cans increased by 106%, and it is expected to reach $13 billion in 2020, accounting for 1/4 of the global total.

Classification of metal cans

At present, there is no official uniform specification and clear classification method for metal cans. However, according to the difference of the use and manufacturing process of metal cans, we can classify them into two kinds of beverage cans, three beverage cans, three food cans, milk powder cans, gas mist cans, steel cans and mixed cans.

The future development trends of metal packaging include: metal packaging reduction in line with energy saving and emission reduction, green packaging industry development keynote; special-shaped tank, special effect printing and plastic cover innovation oriented to milk powder can help the brand to improve the market competitiveness; consumers' esteem for simplified packaging design is affected. Requirements for packaging and decoration, such as "one can and one yard" and the application of AR (Augmented Reality, augmented reality) technology, have made metal packaging digitalized.

The reduction of metal packaging meets the industry development keynote of energy saving, emission reduction and green packaging.

The global climate is getting worse and worse. International environmental policies have put forward higher requirements for metal packaging, avoiding excessive packaging, saving resources, and reducing emissions have become the key to the development of future packaging industry, and the reduction of metal packaging is the trend of the times.

There are four ways to realize the reduction of metal packaging.

First, by improving the mechanical processing technology and changing the packaging structure, the purpose of "improving the strength of the tank and reducing the amount of metal material" has been achieved.

The second is to reduce the reduction of metal materials through the renovation of beverage filling technology. In the use of the beverage cans, the nitrogen replacement is used to replace the high temperature sterilization. Through the technological innovation of the sterilizing kettle, the dynamic anti pressure sterilization is adopted to ensure that the pressure difference inside and outside the tank is minimized.

The third is the material basis. New materials, such as DR (two cold rolled tin plate) and the wide application of JATT materials developed by JFE Steel Corp in Japan, provide a good material basis for the reduction and tank type differentiation. The strength of the DR material is good, while the thickness of the material is directly reduced, and the axial and radial strength of the tank can not be weakened. However, due to the poor processing performance of DR, the process of flanging, rib rolling, stretching and necking will be more difficult in the process of making cans. By adjusting the structure of metal molecules, JATT material effectively improves the processing performance of metal. At the same time, through two cold rolling, it has the same strength of DR material, which provides a better solution for the processing and profiling of metal cans.

The fourth is to reduce the use of chemicals. Through the simple design of the decoration pattern, avoid over printing. In addition, the application of new technology and new materials such as UV printing, waterborne coatings and coated iron has greatly reduced the use of chemical substances and reduced the emission of VOCs.

Packaging differentiation to help brand promote market competitiveness

With the change of consumers' aesthetic standards, people are increasingly fastidious about the appearance of packaging products, so that irrrgular cans are becoming more and more popular. The manufacturers of packaging products are constantly studying and designing new structure and appearance of metal packaging, changing the singleness of packaging to improve the attractiveness of the product shelves and promoting the competitiveness of the brand market. A consumer with personality traits and preferences.

Figure 2: with the change of consumer aesthetics, people are increasingly fastidious about the appearance of packaging products,

so that special shaped cans are becoming more and more popular.

In the past nearly 200 years, there has been no change in the structure and shape of the standard canisters of food and beverage, which has caused visual fatigue to consumers in the past nearly 200 years. The rapid development of pot making technology provides more possibilities for the structure and appearance differentiation of metal cans. Through the technology of tank expansion, necking, rolling and rolling, and metal surface stamping and rolling technology, the tank factory produces different shaped tanks with different structure and appearance, and the following are the products which have been different in structure and appearance on the market.

Picture 3 In the market, the structure and appearance differentiated products include

waist drum milk cans, special beer cans and so on.

The development of special effect printing iron technology provides more options for the differentiation of metal packaging products, such as explosive light oil, dumb light oil, laser printing technology, warm ink and so on. It has been widely used in some high-end daily necessities packaging and dry fruit packaging.

explosive vanish laser printing temperature sensitive ink dumb light ink

Figure 4 The development of metal printing technology, including explosive vanish, laser printing technology, temperature

sensitive ink and dumb light ink,provides more options for the differentiation of metal packaging products.

The plastic cover has become a part of the differential innovation of the milk powder cans. The metal milk powder can have its particularity, such as the longer service life, the higher additional value, the two sealing requirements, etc. Therefore, the use of plastic cover to enhance the competitiveness of packaging products has become an effective way for milk cans manufacturers and users in the future.

With the advantages of more convenient opening of the female and female covers, the utilization rate of the aluminum foil easy to tear is higher and higher. However, the aluminum foil can not tear off the lid for two times. After opening, it is easy to absorb moisture in the process of using milk powder. By designing and manufacturing plastic cover with good sealing performance, it can effectively solve the problem of two times sealing of milk powder cans. At the same time, the diversification of processing performance makes the plastic cover have the potential of continuous innovation, which greatly improves the differentiation of packaging products. In short, the innovation of plastic cover has become part of the innovation of milk powder pots.

The change of consumption concept has affected the requirements of packaging and decoration.

Simplicity is a fashionable and environmentally friendly packaging design. On the one hand, the simple design conforms to the aesthetic view of the contemporary young people, the smooth and concise lines, the contrasting color makes the packaging have a higher sense of grade and artistic sense. On the other hand, the simple printing pattern design can greatly simplify the printing process, minimize the use of chemical materials such as paint, ink and so on, thus reducing the emission of VOCs, at the same time, it also reduces the possibility of the migration of harmful chemicals in the production process of food packaging, and improves the safety of the packaging. The cost of manufacturing is reduced.

The following is a classic application case of simple design on two cans.

Figure 6: simplicity is a fashionable and environmentally friendly packaging design.

Digitalization of metal packaging

Following the packaging of paper, nowadays, "one can and one yard" has become ubiquitous in the field of metal packaging. The unique and variable digital two-dimensional code is sprayed on the packaging by inkjet printing equipment, and each two-dimensional code is unique. Two dimensional code has injected new vitality into packaging. It can make packaging the only one, and give the packaging diversity. The uniqueness of the package can be traced through the scanning variable two-dimensional code, to prevent the counterfeiting, and to prevent the collection of the goods. In addition, the integration and reward can also be exchanged through the scavenging code. The packaging that has the characteristics of diversity can even be connected through two dimensional code connections to make the package more rich, such as connecting websites, advertising films, and animated short films.

Figure 7. Two dimensional code has injected new vitality into packaging. It can make packaging the only

one and give the packaging diversity.

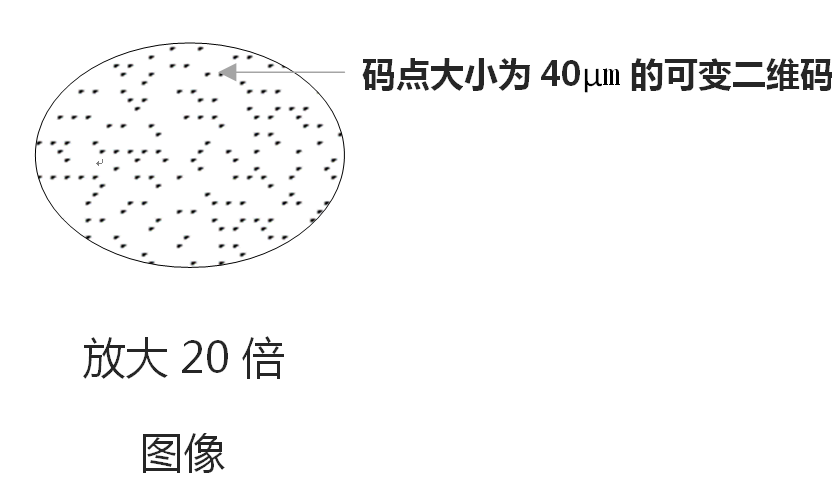

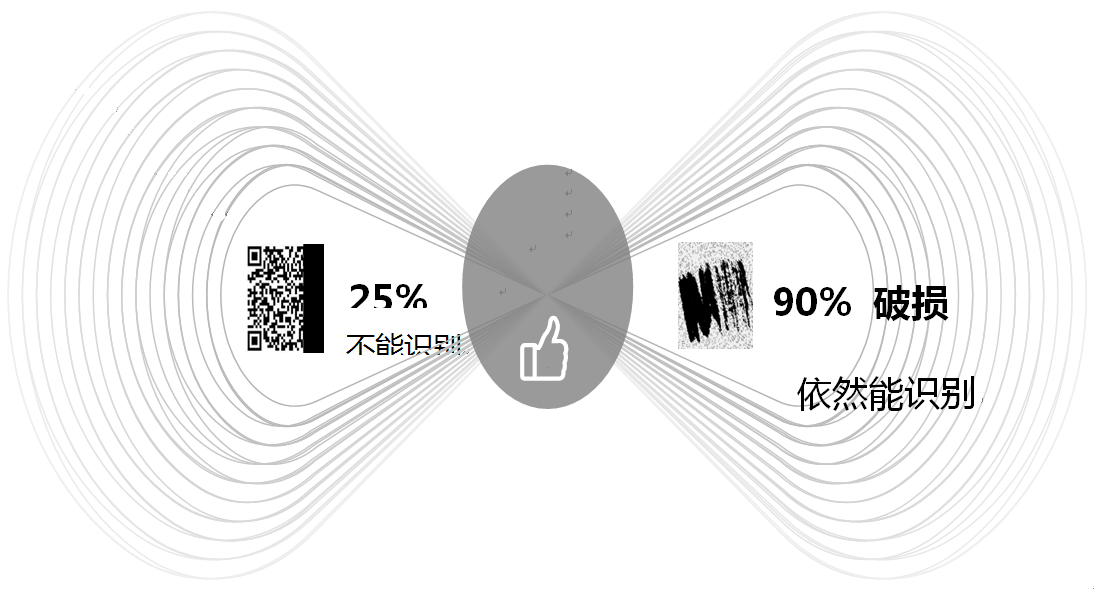

As the ink-jet "two-dimensional code" is vulnerable to external factors, it is vulnerable to damage, failure, and easy to be malicious scavenging, Shenzhen city full packaging Co., Ltd. combined with relevant research and development agencies to launch a "microcode" technology. The size of the "two-dimensional code" is reduced to 40 m through a patent algorithm, layer encryption, and the use of high-definition overlying code, and the number of "microcodes" can be made up of a visible "two-dimensional code", so that even in the vast majority of damaged cases, the visible "two-dimensional code" can obtain data through a scavenging code. In addition, in order not to affect the effect of the printed pattern, "microcode" can also be printed in a specific area of the tank by stealth printing technology, and then use a specific scavenging device to read "invisible two-dimensional code", which greatly improves the effectiveness of "anti cross".

In Figure 8, in microcode, the size of the "two-dimensional code" is reduced to 40 m, and the number of "microcodes"

can be made up of a visible "two-dimensional code", so that even in most cases, the visible

"two-dimensional code" can still obtain data through a scavenging code.

The application of AR technology is a technology that calculates the location and angle of the camera image in real time and adds the corresponding image in order to put the virtual world on the screen and interact in the real world. By using a mobile camera to take a picture of a particular pattern, a moment can instantly move the pattern and present it in front of it. At the same time, the specific scene can be displayed in front of the front, just as in real life, it greatly improves the sense of technology and artistry of the metal packaging.

Conclusion

The above summarizes the problems and development trend of metal packaging. Especially in the Internet era, we have to reexamine the metal packaging that has remained unchanged for the past 200 years. It is no longer a simple package, but is being given a new mission. It can be a medium of information, and it can also integrate advertising, entertainment and knowledge into one.